I found out via youtube (researching the Arduino) about MAKEZINE.COM

One of the many exciting projects they share was this 3D puzzle: http://blog.makezine.com/archive/2009/12/make_projects_-_easy_3d_models_with.html

Its excellent, for example it is a great way to practice using 3D software and rapid prototyping. Even suitable for a lazer cutter. The tutorial talks about OpensSCAD (from makezine.com):

I wrote a couple of weeks ago about the excitement surrounding Clifford Wolf's new freeware OpenSCAD program. OpenSCAD uses a cool keep-it-super-simple approach to 3D modeling, eliminating the resource-hungry what-you-see-is-what-you-get (WYSIWYG) editing environment favored by most 3D modeling packages, and replacing it with a text-based scripting environment in which models are programmed, instead of sculpted. Basically, you write a script describing your model's shape and then compile it to produce the actual model, which is then rendered onscreen and can be exported to STL format for 3D printing or other purposes.

OpenSCAD has two powerful features to facilitate this programming processes. The first is support for so-called "constructive solid geometry" (CSG) modeling, in which complex forms are built up as intersections, unions, and differences of simple primary shapes like boxes, cylinders, cones, and ellipsoids. If you've ever used the ray-tracing program POV-Ray before, this idea will be familiar to you.

The second, less-well-publicized (but perhaps equally powerful) feature of OpenSCAD is "DXF extrusion," in which OpenSCAD will import a 2D drawing in AutoCAD's popular drawing exchange format (DXF) and "extrude" it into the third dimension. OpenSCAD has support for linear extrusion, in which the resulting part has straight vertical sides, and also rotating extrusion, which results in a part with helical sides. Since a large number of models for rapid prototyping are simple extruded profiles, I expect this feature to see a lot of use.

In this tutorial, I'm going to show you how to use OpenSCAD to produce a simple 3D model by extruding a part profile produced in normal drawing software. I use Adobe Illustrator CS3 because I have access to it and am familiar with its interface, but the popular freeware drawing program InkScape will read and write DXF files natively, and there's no reason why it couldn't serve just as well if you prefer it. There are a number of other free and low-cost programs that will export DXF files. OpenSCAD's developer mentions QCAD, which is available from its developer RibbonSoft for €24.

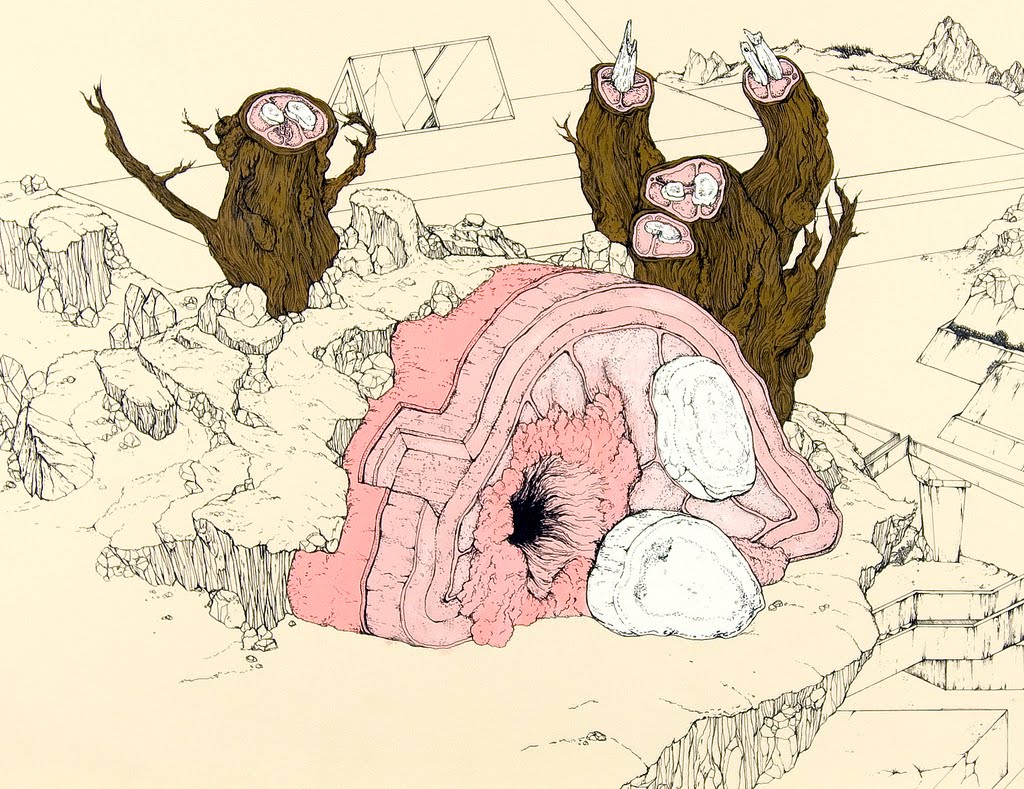

Its basically amazing, and brilliant for any one who goes to University of the Arts who is even remotely interested in rapid prototyping. These images are all from the tutorial. It clearly describes exactly how to use the software.