Wikipedia: Rapid prototyping is the automatic construction of physical objects using additive manufacturing technology. The first techniques for rapid prototyping became available in the late 1980s and were used to produce models and prototype parts. Today, they are used for a much wider range of applications and are even used to manufacture production-quality parts in relatively small numbers. Some sculptors use the technology to produce complex shapes for fine arts exhibitions.

It works by 'printing' layers of plastic that are only just molten one on top of the other. It does so with two types of plastic; one which makes up the actual model and one which is a support, which is added if necessary and can be broken down in some kind of solution (revealing only the model).

This opens whole can of worms. Not only IS everything possible (regarding you master to some degree at least the basics of 3D modeling- which is very difficult I have been told or find someone to help you do it) BUT also this has introduced the possibility to make stop frame animation of a physical work, which is something I am very interested in doing at a later point while at Camberwell.

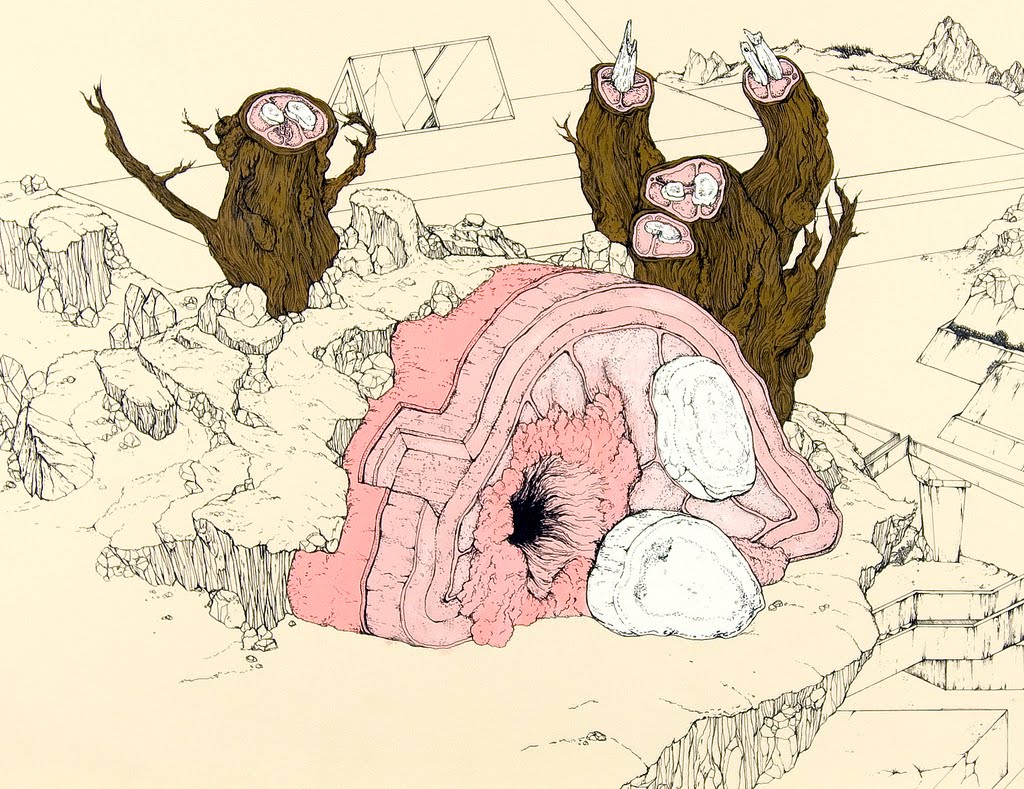

Im more determined (not just mildly interested) in learning how to use a new software, any software that can make this possible. The machinery used to develop these real models is fascinating. Theoretical and practical all in one operation! Another interesting thing about this process is that one could possibly make casts of models with plaster or clay to be filled with any other material or use 3D lazer scanning of other objects for example. Possibilities are immense. Examples below from google image search.

It works by 'printing' layers of plastic that are only just molten one on top of the other. It does so with two types of plastic; one which makes up the actual model and one which is a support, which is added if necessary and can be broken down in some kind of solution (revealing only the model).

This opens whole can of worms. Not only IS everything possible (regarding you master to some degree at least the basics of 3D modeling- which is very difficult I have been told or find someone to help you do it) BUT also this has introduced the possibility to make stop frame animation of a physical work, which is something I am very interested in doing at a later point while at Camberwell.

Im more determined (not just mildly interested) in learning how to use a new software, any software that can make this possible. The machinery used to develop these real models is fascinating. Theoretical and practical all in one operation! Another interesting thing about this process is that one could possibly make casts of models with plaster or clay to be filled with any other material or use 3D lazer scanning of other objects for example. Possibilities are immense. Examples below from google image search.

Objet 3D Printers consist a family of 3D rapid prototyping machines that allow users (and

ReplyDeletethis is the cool part) within the office environment to transform a CAD image to a 3d model in a matter of minutes.